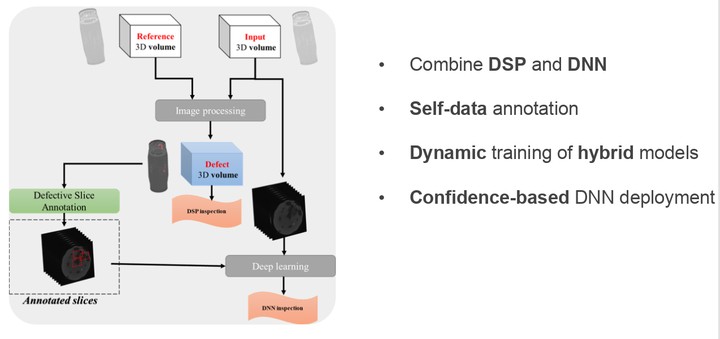

The framework of the CTIMS project.

The framework of the CTIMS project.Abstract

Non-Destructive Testing (NDT) is one of the inspection techniques used in industrial tool inspection for quality and safety control. It is performed mainly using X-ray Computed Tomography (CT) to scan the internal structure of the tools and detect the potential defects. In this paper, we propose a new toolbox called the CT-Based Integrity Monitoring System (CTIMS-Toolbox) for automated inspection of CT images and volumes. It contains three main modules. First, the database management module, which handles the database and reads/writes queries to retrieve or save the CT data. Second, the pre-processing module for registration and background subtraction. Third, the defect inspection module to detect all the potential defects (missing parts, damaged screws, etc.) based on a hybrid system composed of computer vision and deep learning techniques. This paper explores the different features of the CTIMS-Toolbox, exposes the performance of its modules, compares its features to some existing CT inspection toolboxes, and provides some examples of the obtained results.

This project was led by Prof. Hossam A. Gabbar and me as the postdoctoral researcher of the team (composed of two master’s students [ Md Jamiul Alam Khan , Oluwabukola Grace], software developer Matthew Immanuel Samson, and a lab engineer Manir Islam) in collaboration with New Vision Systems Canada Inc. (NVS) and Mitacs.

For a CTIMS demo, please feel free to send an email to Amr Barakat (amrb@nvscanada.ca)

This work was supported by New Vision Systems Canada Inc. (NVS) and Mitacs. The authors would like to thank the collaborators from Diondo and Fraunhover, Germany.